Where Quality Meets Efficiency – The New Manufacturing Standard

The optimal solution for today’s challenges and tomorrow’s growth.

Speed without compromise. Precision without complexity.

Developed with direct feedback from the factory floor, our AI solutions deliver the intuitive tools that they’ve long needed – seamless, plug-and-play performance.

Beyond automated visual inspection, our system supports continuous improvement through built-in recording, analysis, and retraining functions.

Designed with flexibility and simplicity in mind, it empowers non-technical staff to operate and improve performance without relying on engineers.

From small-batch production to high-volume lines, our solutions are trusted across a wide range of industries.

A solid answer – now and down the line.

01

AI Image Processing Software

A powerful image analysis tool that balances simplicity and precision – no expertise required.

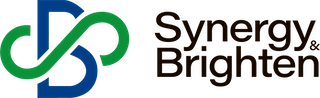

Developed by Synergy & Brighten, our AI-powered system is specialized for automating defect and anomaly detection in factory environments, ensuring consistent quality control without relying on human operators.

AI is a technology that nurtures vision.

AI is a technology that nurtures vision.

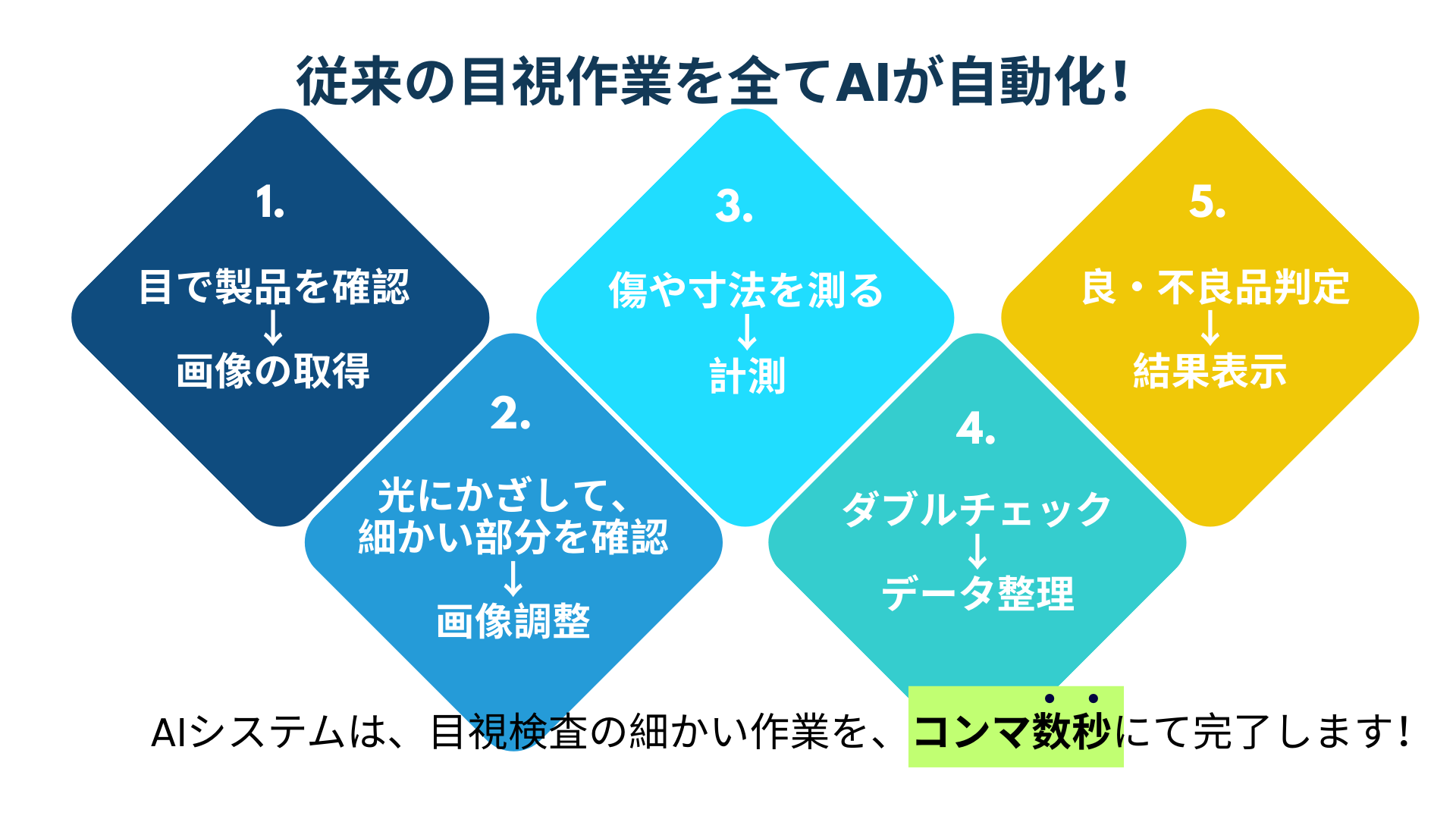

Our AI system doesn’t stop at the point of sale. Our system is built for continual learning. By leveraging real inspection data gathered from actual opeations–including edge cases and envioronmental shifts–we ensure long-term accuracy and reliability that evolves with your production.

This iterative learning process allows AI to automate even those nuanced judgements traditionally handled only by skilled technicians.

Customizable Hybrid Systems Tailored to Your Factory Needs

Customizable Hybrid Systems Tailored to Your Factory Needs

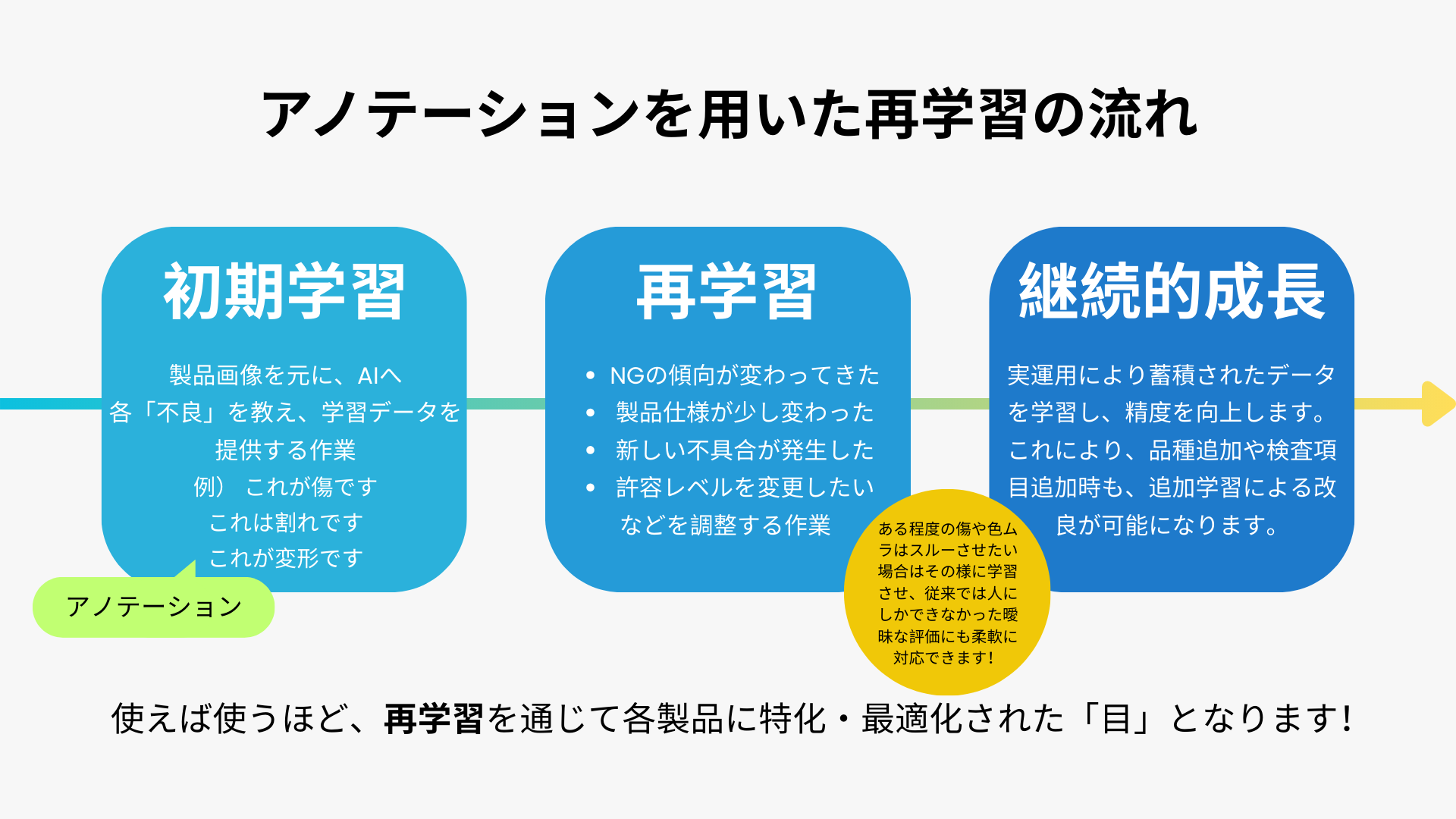

At Synergy & Brighten, we develop intelligent AI inspection solutions tailored to your factory–whether you’re building from scratch or upgrading existing systems.

Our hybrid approach combines only the software and hardware you need, ensuring smooth integration, cost-efficiency, and alignment with your workflow and space.

Even if you already have cameras or inspection equipment, our AI software can be introduced as a standalone module. With everything developed in-house, we provide systems that are precise, practical, and built to meet real on-site needs.

Case Studies

- Forged Parts Inspection

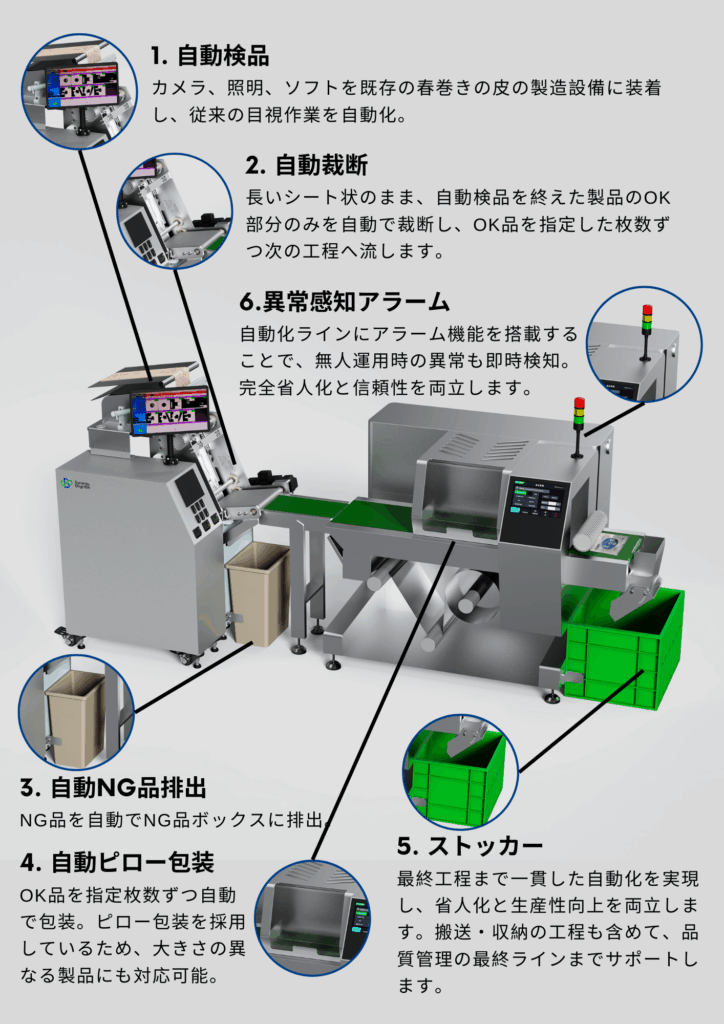

- Spring Roll Wrapper Inspection

Case Studies

- Forged Parts Inspection

- Spring Roll Wrapper Inspection

02

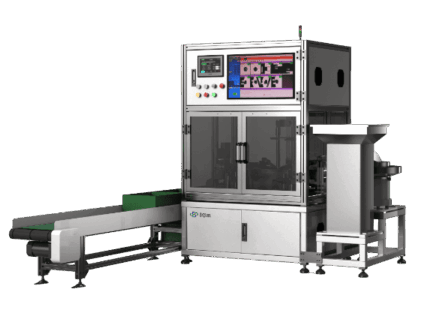

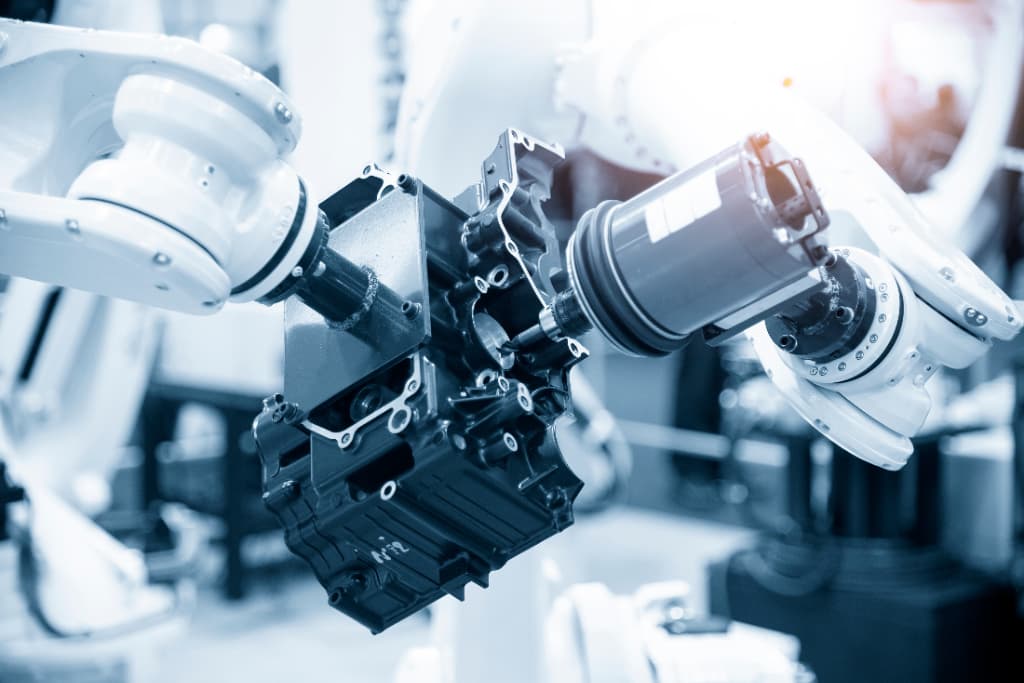

Automation Equipments

We design and build tailor-made automation systems that reflect the unique challenges of your site and the characteristics of your products.

By integrating AI-powered control, we help achieve both workforce reduction and consistent quality.

Discover how we deliver results–visit our success stories and product catalogue!

We design and build truly one-of-a-kind automation systems, each uniquely crafted to suit the specific challenges of your product and production site.

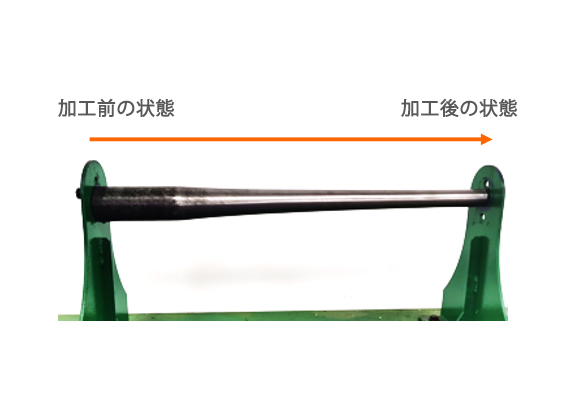

Forged Parts Inspection

Reliable performance even in harsh environments

Food Cutting & Packaging

Hygiene and speed, perfectly handled.

Carton

Assembly

Custom-built to fit your product and shape!

Dimensional Inspection

High-speed detection at micron-level precision.

03

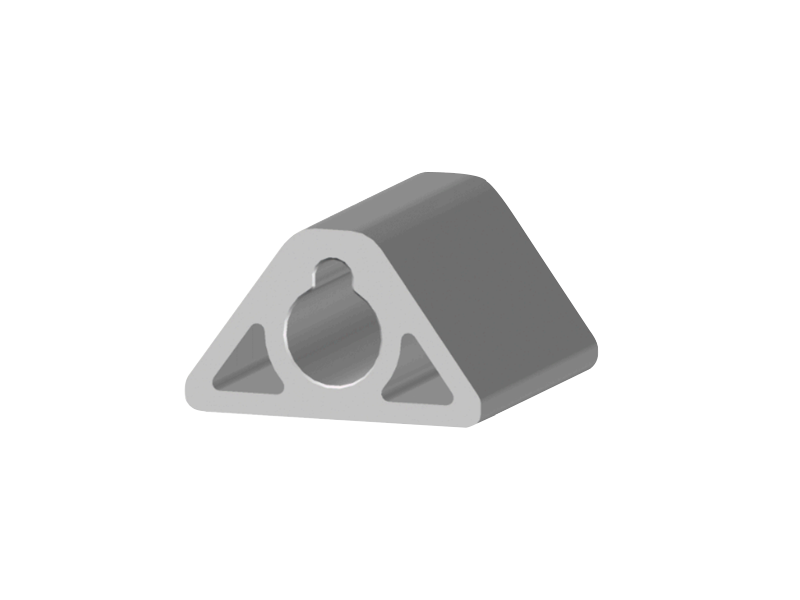

Industrial Manufacturing

From metal to resin, Synergy Group also specializes in on-demand production and sales of technical manufacturing materials.

Ease the burden of parts procurement through a stress-free supply model, even in small-lot runs!

While classified as a 6000-series aluminum alloy known for excellent extrudability, it achives high strength comparable to SS400 strucutural steel.

04

AI Visual Inspection System

Multi-angle inspection that captures what the human eye may miss–ensuring high-precision defect detection. Designed for speed and stability, the system supports fast conveyance and automatic rejection for continuous operation in large-scale production.

Examples of Inspectable Defects

Metal Production

- Cracks/Chips

- Burrs

- Dimensional misalignment

- Deformation/Dents

- Rust/Cavities

Food Production

- Tears/Burns

- Dents/Scratches

- Foreign objects/Stains

- Printing errors

- Contamination

Plastics & Elastics

- Silver streaks

- Scratches/Streaks

- Strains

- Discoloration

- Bubbles

Electronics

- Foreign objects/Contamination

- Short Circuits

- Disconnections

- Solder deficiencies

CPG

- Printing errors

- Blurred or faded prints

- Foreign objects/Contamination

- Stains

- Torn or misaligned labels

Sheet Molding

- Pinhole

- Lens

- Gel

- Bubbles

- Crack

05

3D Picking

Leveraging advanced 3D recognition, our AI system identifies randomly piled workpieces and autonomously determines the most efficient picking motion. It turns complex, unstructured part arrangements into fully automated workflows–removing a major barrier to seamless part feeding.

With our purpose-built–AI, your picking operations take one step further–beyond conventional automation.

Gripping Accuracy

By utilizing AI and camera technologies, the system detects the angle and position of each object with high precision–enabling accurate recognition and gripping of randomly arranged parts

Handling of Irregular Shapes

Even for workpieces with complex or irregular shapes, the AI automatically determines and adjusts the optimal picking point–ensuring smooth and efficient retrieval.

Improved Operational Speed

Compared to conventional 2D picking, our system delivers a significant boost in efficiency. It reduces pick errors and unnecessary movements, enabling a stable and faster cycle time.

Versatile Application

By adjusting the settings to match the size and material, our system can flexibly support a wide range of manufacturing scenarios–from small-lot, high-mix production to full-scale mass production.

06

Robot Dispatch

We offer a flexible subscription-based plan that allows you to deploy AI-equipped robots on a monthly basis. Whether you’re dealing with seasonal demand, labour shortages, or simply want to start with a trial implementation, our solution is available when and as you need it.

Up and running in just 3 simple steps!

1. On-site Assessment & Consultation

We begin by understanding your production site and operational challenges. Based on this, we propose the most suitable robot specifications and integration approach tailored to your environment.

2. Robot Selection & Customization

We help you select the ideal robot configuration for your needs. Your only upfront cost is installation and any custom grippers. You can then choose the most suitable operation plan based on the level of support and services you require.

3. Installation and Initial Training

We install the robot and custom gripper on-site, then fine-tune the motion and picking parameters to match your target workpieces.