Purpose of Implementation

Eliminate quality differences caused by variability in visual inspection skills.

Reduce labour and personnel costs through automated defect detection.

Challenges Before Implementation

Since its founding, Zuihousha has operated under the motto of “delivering products trusted by our customers and clients,” continuously striving to maintain stable, high-quality standards.

However, in recent years, rising material and labour costs highlighted the limitations of relying solely on human visual inspection for production efficiency. Additionally, concerns arose over the potential for human inspectors to overlook subtle defects such as tiny holes or colour variations, making stricter inspection standards necessary.

The company needed a solution that could simultaneously improve quality control and reduce labour effort, addressing these two seemingly conflicting goals.

Three Reasons for Choosing Our Inspection System

- Simultaneous Improvement in Quality Control and Production Efficiency

The system was valued for its ability to reconcile the conflicting needs of “strengthening quality control” and “enhancing production efficiency.” By automatically detecting subtle defects or colour variations that human inspectors might miss, the system reduces the burden on craftsmen while maintaining high-quality standards. - Design Suitable for Food Hygiene and Flexible Integration with Existing Equipment

Designed with stainless steel for hygienic handling of food products, the system features a touchscreen interface, allowing operators to manage equipment easily and safely within the food processing area. It integrates seamlessly with existing machinery without disrupting workflows, an important consideration for the production floor. - Cost Performance

Despite offering high-precision defect detection tailored to thin spring roll wrappers and varying bubble types, the system maintains affordable installation and operating costs, making it highly attractive from a cost-performance standpoint.

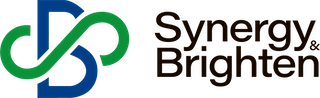

About the Implemented Product

For Zuihousha’s production line, we carefully analyzed challenges such as AI decision feasibility, workflow placement, and inspection coverage. The selected model was the Food Sheet Product AI Automated Inspection Machine (Supervised Learning Model).

This model leveraged our strength of providing software and hardware as an integrated system and allowed maximum flexible customization to meet Zuihousha’s production line needs.

Implementation Effects

Maintaining and Improving Production Efficiency

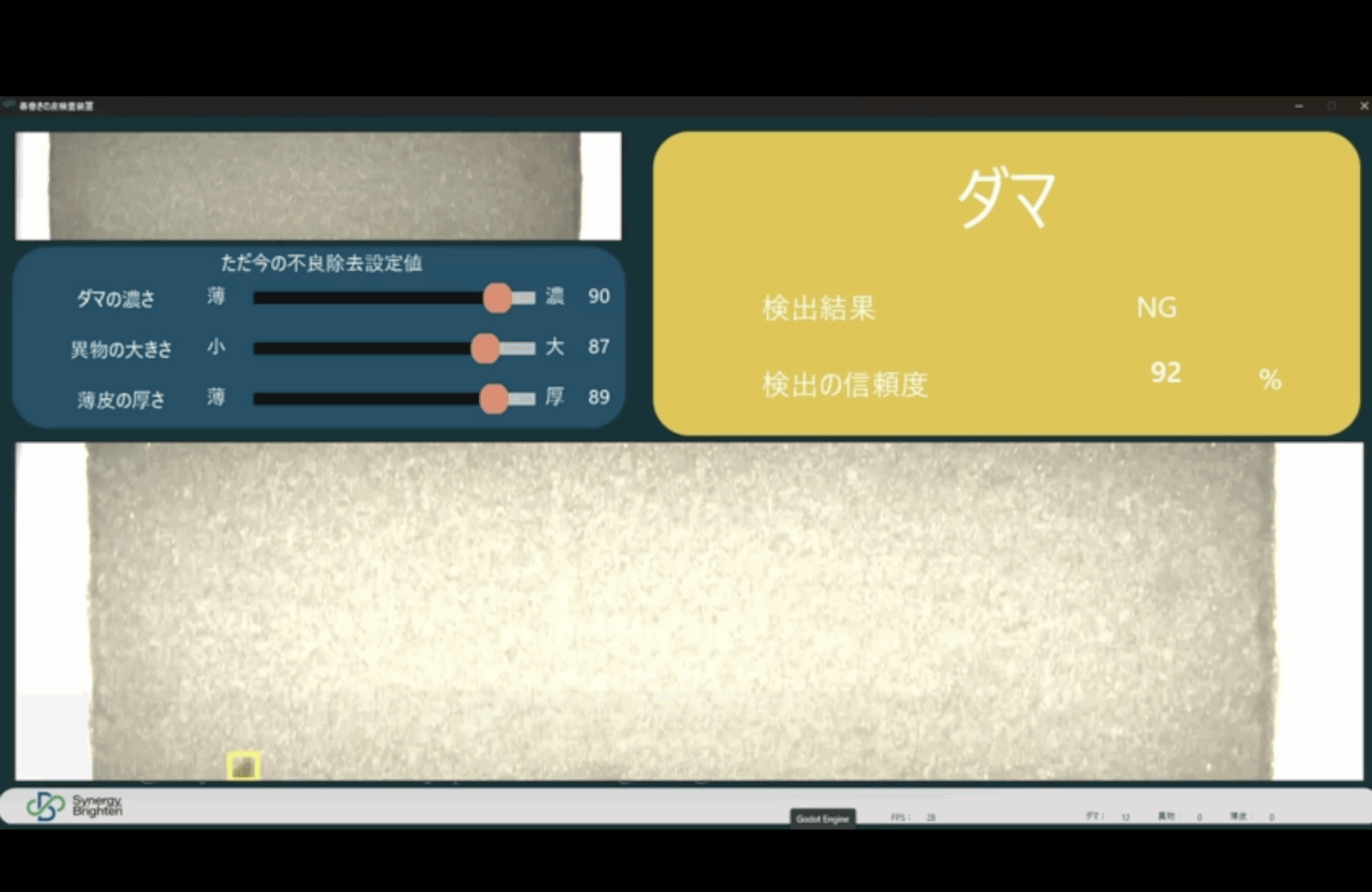

Products moving along the belt are illuminated from above and captured at over 50mm per second from below. Images are sent to the AI in real time, automatically detecting defects such as foreign objects, lumps, or scratches on every corner of the spring roll wrappers. This significantly improved production efficiency.

Enhanced Quality Control Accuracy

The supervised learning model collects data for each defect type and trains the AI, enabling human-level judgment for subtle defects, maintaining Zuihousha’s high-quality standards.

Cost and Labour Reduction

When defects are detected, the system alerts operators via colour-coded indicators and alarms for different defect types, enabling rapid response as needed.

Maintaining Food Hygiene Standards

Our integrated software and hardware solution ensures hygienic equipment construction using food-grade stainless steel, while allowing seamless integration with other production equipment.

Future Outlook

With the AI inspection system, Zuihousha has established a new standard for production efficiency. The company is now considering introducing 3D picking and automated packaging equipment, aiming to further enhance production efficiency and quality control through seamless integration with other equipment.

About Zuihousha Co., Ltd.

Founded in January 1983 and based in Aisai, Aichi, Zuihousha is a food manufacturer producing a variety of Chinese ingredients, including gyoza wrappers, shumai wrappers, wonton skins, spring roll wrappers, and fresh Chinese noodles. With around 40 years of experience and technical expertise, the company delivers safe, high-quality products, earning trust domestically and internationally.