Where Quality Meets Efficiency – The New Manufacturing Standard

The optimal solution for today’s challenges and tomorrow’s growth.

Speed without compromise. Precision without complexity.

Developed with direct feedback from the factory floor, our AI solutions deliver the intuitive tools that they’ve long needed – seamless, plug-and-play performance.

Beyond automated visual inspection, our system supports continuous improvement through built-in recording, analysis, and retraining functions.

Designed with flexibility and simplicity in mind, it empowers non-technical staff to operate and improve performance without relying on engineers.

From small-batch production to high-volume lines, our solutions are trusted across a wide range of industries.

A solid answer – now and down the line.

01

AI Image Processing Software

A powerful image analysis tool that balances simplicity and precision – no expertise required.

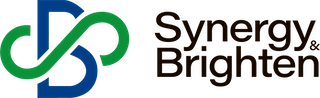

Developed by Synergy & Brighten, our AI-powered system is specialized for automating defect and anomaly detection in factory environments, ensuring consistent quality control without relying on human operators.

AI is a technology that nurtures vision.

AI is a technology that nurtures vision.

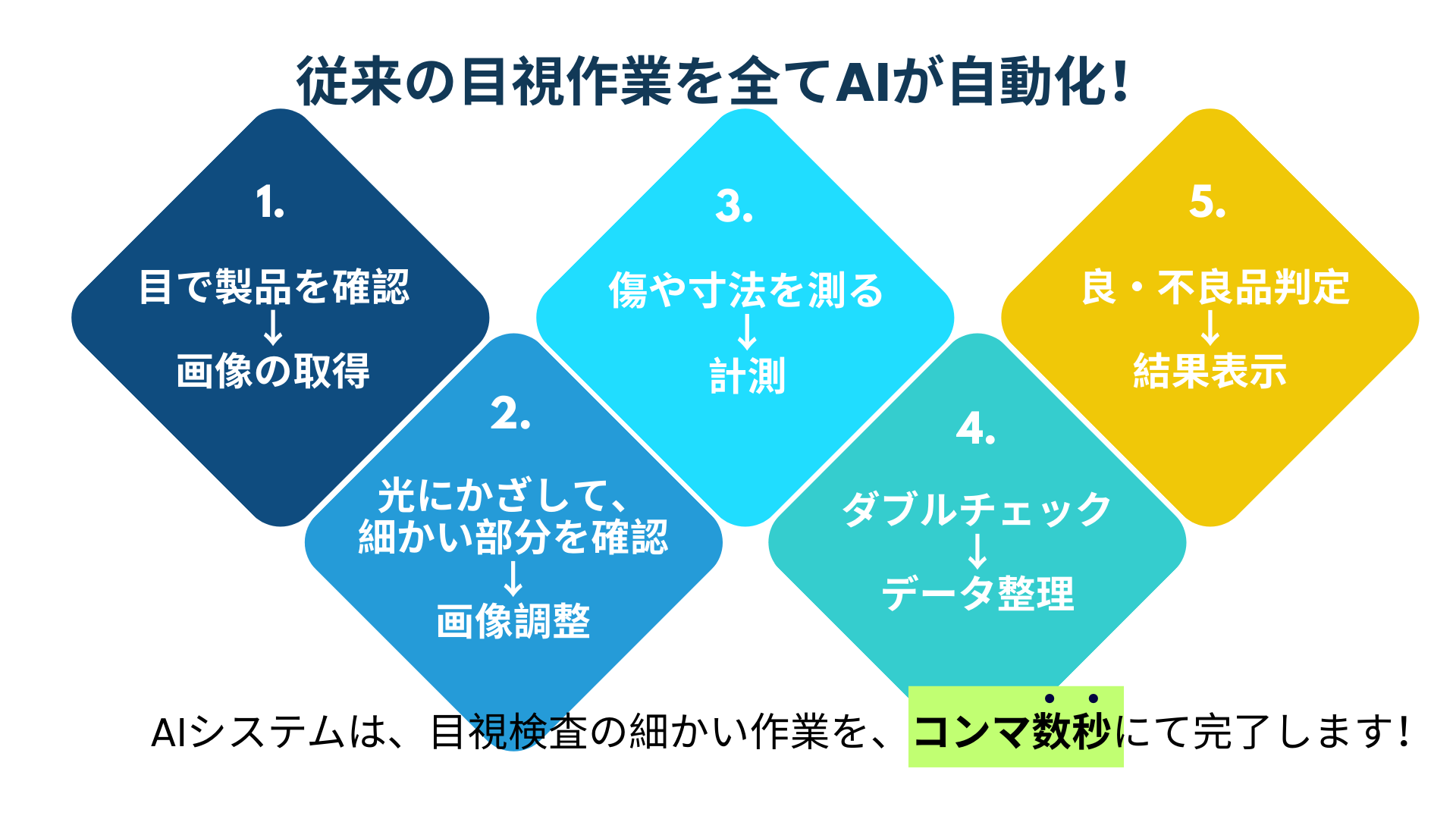

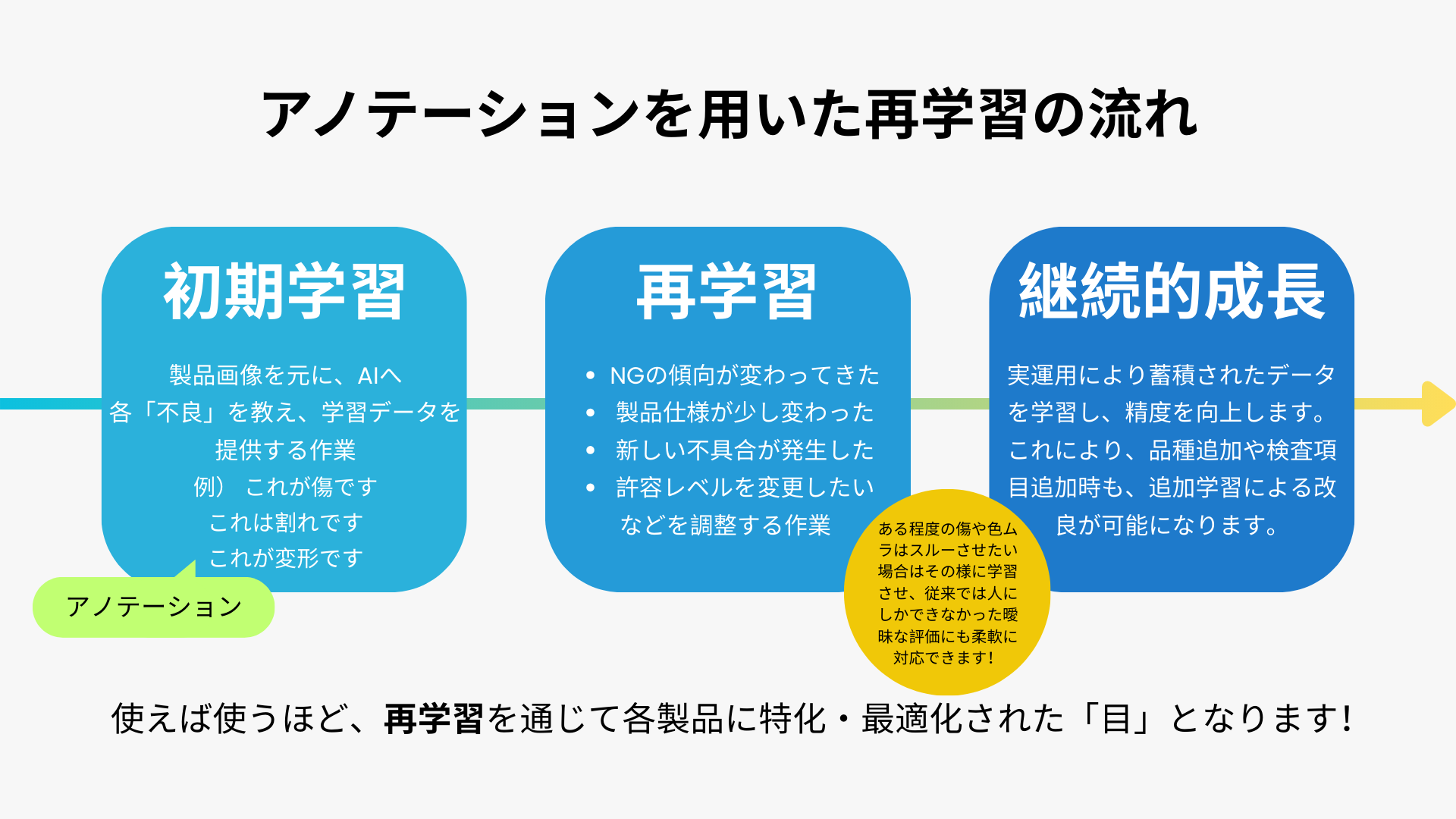

Our AI system doesn’t stop at the point of sale. Our system is built for continual learning. By leveraging real inspection data gathered from actual opeations–including edge cases and envioronmental shifts–we ensure long-term accuracy and reliability that evolves with your production.

This iterative learning process allows AI to automate even those nuanced judgements traditionally handled only by skilled technicians.

Customizable Hybrid Systems Tailored to Your Factory Needs

Customizable Hybrid Systems Tailored to Your Factory Needs

At Synergy & Brighten, we develop intelligent AI inspection solutions tailored to your factory–whether you’re building from scratch or upgrading existing systems.

Our hybrid approach combines only the software and hardware you need, ensuring smooth integration, cost-efficiency, and alignment with your workflow and space.

Even if you already have cameras or inspection equipment, our AI software can be introduced as a standalone module. With everything developed in-house, we provide systems that are precise, practical, and built to meet real on-site needs.

Case Studies

- Forged Parts Inspection

- Spring Roll Wrapper Inspection

Case Studies

- Forged Parts Inspection

- Spring Roll Wrapper Inspection

02

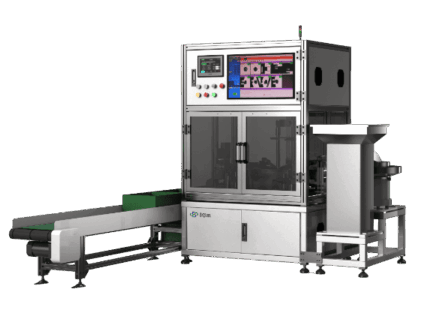

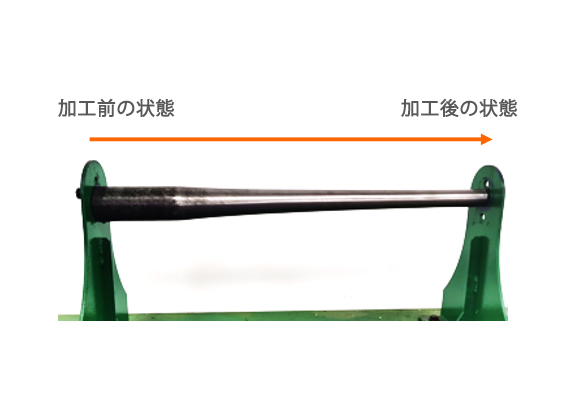

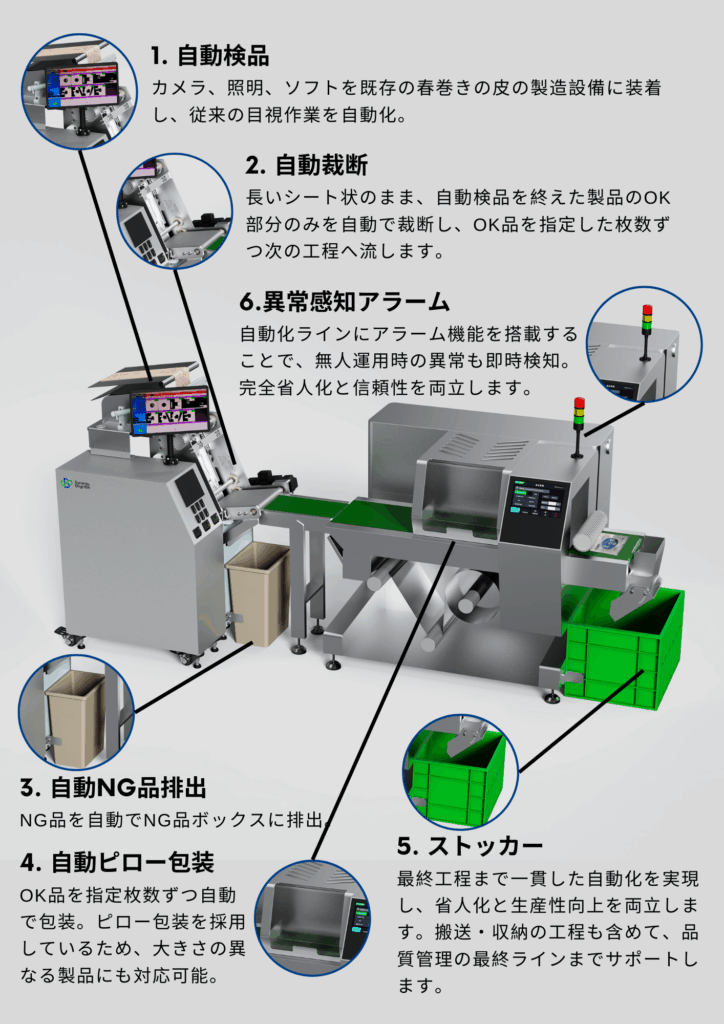

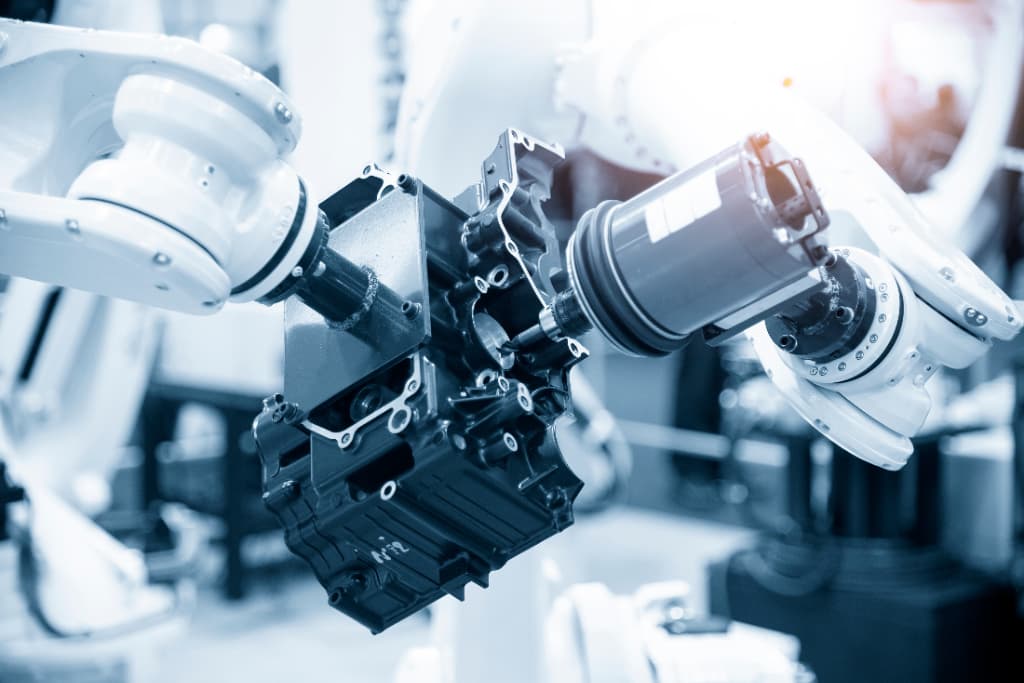

Automation Equipments

We design and build tailor-made automation systems that reflect the unique challenges of your site and the characteristics of your products.

By integrating AI-powered control, we help achieve both workforce reduction and consistent quality.

Discover how we deliver results–visit our success stories and product catalogue!

We design and build truly one-of-a-kind automation systems, each uniquely crafted to suit the specific challenges of your product and production site.

Forged Parts Inspection

Reliable performance even in harsh environments

Food Cutting & Packaging

Hygiene and speed, perfectly handled.

Carton

Assembly

Custom-built to fit your product and shape!

Dimensional Inspection

High-speed detection at micron-level precision.

03

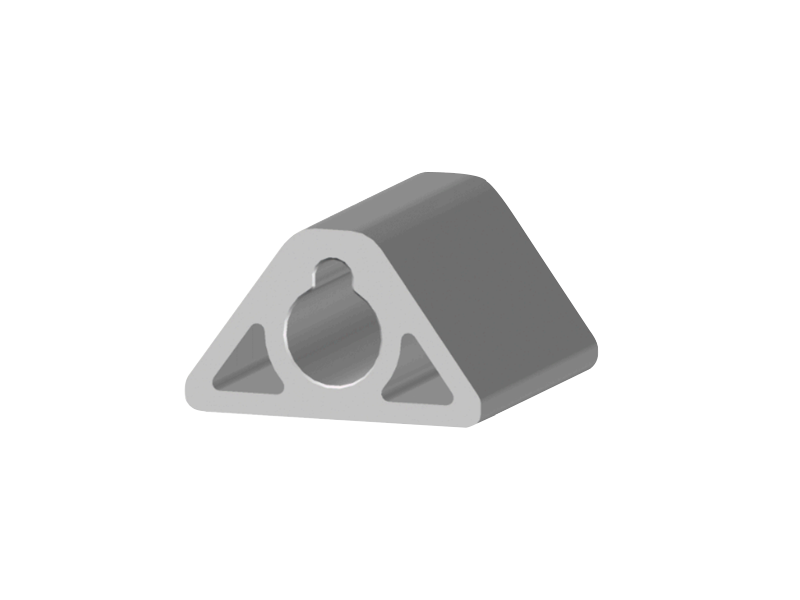

Industrial Manufacturing

From metal to resin, Synergy Group also specializes in on-demand production and sales of technical manufacturing materials.

Ease the burden of parts procurement through a stress-free supply model, even in small-lot runs!

While classified as a 6000-series aluminum alloy known for excellent extrudability, it achives high strength comparable to SS400 strucutural steel.

04

AI Visual Inspection System

Multi-angle inspection that captures what the human eye may miss–ensuring high-precision defect detection. Designed for speed and stability, the system supports fast conveyance and automatic rejection for continuous operation in large-scale production.

Examples of Inspectable Defects

Metal Production

- Cracks/Chips

- Burrs

- Dimensional misalignment

- Deformation/Dents

- Rust/Cavities

Food Production

- Tears/Burns

- Dents/Scratches

- Foreign objects/Stains

- Printing errors

- Contamination

Plastics & Elastics

- Silver streaks

- Scratches/Streaks

- Strains

- Discoloration

- Bubbles

Electronics

- Foreign objects/Contamination

- Short Circuits

- Disconnections

- Solder deficiencies

CPG

- Printing errors

- Blurred or faded prints

- Foreign objects/Contamination

- Stains

- Torn or misaligned labels

Sheet Molding

- Pinhole

- Lens

- Gel

- Bubbles

- Crack

05

3D Picking

複雑に積まれたワークをAIが3次元で認識し、最適なピッキング動作を自動で生成します。従来困難だったバラ積み対応を可能にし、部品供給の自動化を支援します。

専用設計のAIだからこそ、ピッキングに”もう一歩”を加えられます。

把握能力

AIとカメラを活用することで、物体の角度、位置を高精度で検知。ランダムパーツの正確な認識と把持が可能です。

複雑な形状への対応

形状が不規則な製品でも、AIが最適な取り出しポイントを自動で調整、スムーズな取り出しが可能です。

作業スピードの向上

従来の2Dピッキングに比べ、飛躍的な効率化が図れます。ピックミスや無駄な動作を減らし、安定したサイクルタイムを実現します。

適用範囲

サイズや素材に応じて、設定を変えるだけで、多品種少量から大量生産まで、多種多様な現場で柔軟にご使用いただけます。

06

Robot Dispatch

AI搭載ロボットを月額制で導入できる柔軟なプランをご用意しています。繁忙期や人手不足への対応、初期のトライアル導入など、必要な時に必要なだけご活用いただけます。

簡単3ステップで運用準備完了!

1. ヒアリングと現場確認

お客様の製造現場や課題をヒアリングし、最適なロボットの仕様や導入方法をご提案します。

2. ロボットの選定と

運用プランのご選択

初期費用は設置作業+カスタムハンドのみ!サポートの必要頻度などに合わせ、最適な運用プランをご選択いただきます。

3. 設置と初期チューニング

ロボットとハンドを設置し、対象ワークに合わせた動作調整・ピッキング設定を行います。