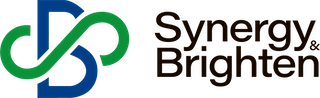

Straight Line AI Image Inspection System

The Straight Line AI Image Inspection System is a high-precision, high-efficiency automated inspection system specialized for visual inspection of forged parts, resin components, and similar items. Utilizing AI and hybrid software, it instantly detects minute defects, foreign objects, cracks, and other issues difficult to spot visually, automatically classifying and processing them.

Key Features

- Enables efficient quality control and data management by automatically judging and sorting good/defective products, while storing and classifying inspection data per product.

- Automatic feed control and material shortage alarm functions minimize troubles during continuous operation.

- Automatic brightness control of the light source ensures stable imaging quality.

- Remote network connectivity enables remote maintenance and support.

- Standard integration of a conveyor, inspection machine, and pallet changer achieves labor and space savings.

Forging (Forming)

Copper Tube Processing

Machining

| Model Number | JCHX-5S |

| Primary Inspection Targets | Metal and resin parts |

| Primary Detectable Items | Cracks, scratches, foreign objects |

| Inspection Size Range | Max. 50mmØx50mm |

| Inspection Speed | Up to 1.2 sec/pc |

| Equipment Dimensions | 1670(L)x816(W)x1500(H)mm |