Turn Inspections into Precision.

–ANOMALIA– Inspections, redefined by AI. SImple. Accurate. For Everyone.

No technical know-how, no complex setup. In just a few days, you’ll have an AI visual inspection system up and running that anyone on the floor can operate.

ANOMALIA brings the trained eyes of skilled inspectors into AI, eliminating variations in accuracy and solving labour shortage challenges at the same time.

Whether for small workshops or large-scale production lines, it adapts seamlessly to your opearation.

Easy to start. Built to last.

Discover the next generation of inspection solutions–designed to work right alongside you.

Smarter Equipment with built-in inspection, made simple.

Stand out from the competition with ANOMALIA AI visual inspection!

Ease of Adoption x High inspection accuracy – earn your customers’ trust with a new kind of proposal: machinery + AI inspection.

Today, many manufacturers struggle with the challenge of automating visual inspection.

Traditional equipment alone cannot fully cover these processes – AI image inspection technology is essential.

ANOMALIA is a simple AI inspection solution that eliminates the need for complex training or setup, making it easy for anyone to use.

It’s the perfect sales tool for equipment companies that want to offer automation systems together with inspection capability.

When your customers ask for “inspection included”, ANOMALIA delivers – with the fastest implementation and the simplest operation.

From inspection system deployment support to joint PoC with end users, our experts in automation and image inspection provide full support every step of the way.

Common Chalenges in Proposal Activities

Your customers have no suitable product available to meet their needs.

Developing image inspection solutions is expensive and often overly complex.

Lacking differentiation, forced into price competition.

ANOMALIA lets you integrate AI inspection into existing equipment, making proposals seamless in the sales process.

Inspection bundled as an option by machine tool manufacturers

In addition to selling the hardwares, you can package visual inspection systems as a value-added option. For customers, this means “machining + inspection” introduced as one complete solution – a strong appeal for enhancing quality assurance and efficiency.

This package becomes feasible because our system is hardware-independent, and flexibly adapt to a variety of machining tools.

For end users, the ability to retrofit onto existing cameras or equipment is often the decisive factor in adoption.

Added value through simple inspection – for automation line manufacturers

As a space-saving AI inspection software, it can be proposed together with automation equipment.

It perfectly matches customer needs where final inspection is not required, but a quick post-processing check is essential. This makes it easy to integrate into line design as part of quality assurance measures.

With its simple user interface, even operators can use it effectively to prevent defective products from passing through the process.

Boost first-time deals with PoC proposals for inspection newcomers

ANOMALIA is able to demonstrate results through a short-term PoC (about 1-2 weeks), even for companies without prior know-how in image inspection. This is particularly valuable for manufacturers engaged in high-mix, low-volume production, where traditional rule-based inspection is difficult to apply. Because it uses an unsupervised model, there is no need to collect defective data, making evaluation easier and lowering the barrier to proposal. This could also benefit in shortened lead time.

Why Partner with Us?

Feature ①

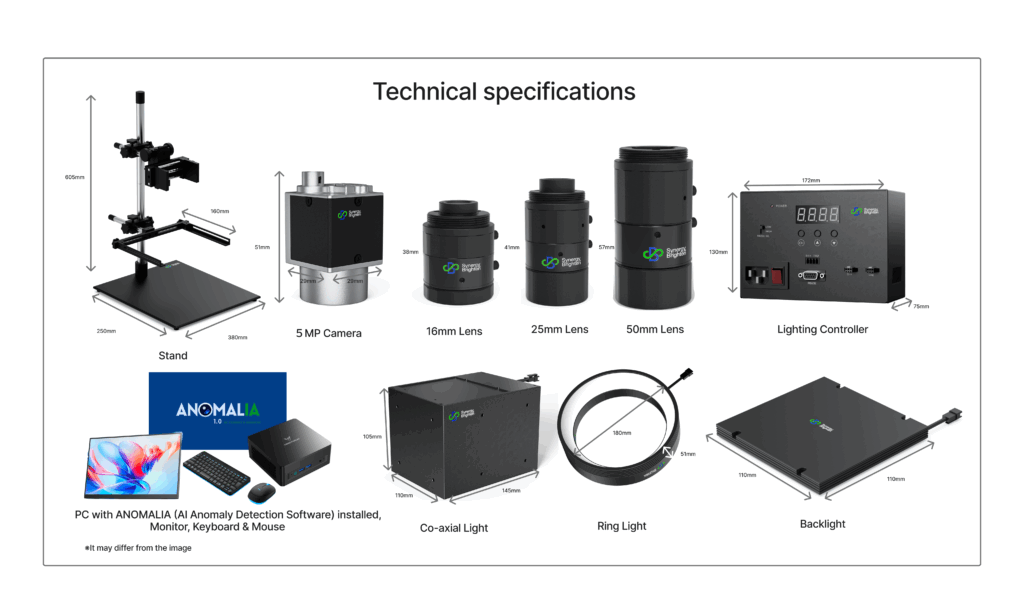

Hardware-independent, retrofit-ready.

ANOMALIA’s image inspection AI is designed with a flexible, harware-agnostic architecture.

This means you can utilize the cameras and lighting already installed on your production line, without the need for large-scale equipment investments or line modifications.

It is an easy proposal even for customers who want to avoid costly equipment upgrades, significantly lowering the barrier to adoption.

Feature ②

AI model validation (PoC) is completed in as little as one week.

This allows you to quickly respond to on-site requests to “try it first”, keeping negotiations moving smoothly. Because the cycle from initial proposal to validation to adoption decision is short, sales efficiency is greatly improved, leading to higher closing rates.

Feature ③

Simple UI that resonates with operators and is easy to explain.

The interface is designed to be intuitive enough for on-site staff to operate without training.

No complicated manuals or setup work are required, which minimizes the explanation burden before and after implementation. Its focus on ease of use makes it highly appealing to both customers and operators on the production floor.

Feature ④

Technical and sales support provided from the proposal stage.

From the very first proposal through PoC and implementation support, ANOMALIA’s technical team strongly backs up your sales activities. We provide support such as answering technical questions, sharing customer-facing presentations and proposal documents, and assisting with sample image capturing.

Our full support team is here to let you move forward with uncertainties.

Sales x Technology

Three Kinds of Partnership Models

Referral: Discover → Refer → Reward

In this model, partner companies identify customers interested in our AI image inspection solutions during their own client visits and interviews, and then introduce them to us.

Designed for:

- Partners such as trading companies and system integrators (Slers)

- Partners with close relationships with manufacturing clients.

Reseller: Sell as your own, backed by our technical support

In this model, partner companies sell and propose our solution as part of their own product portfolio. From the PoC stage through cusotmer proposals, our team provides full technical support.

Ideal for:

- Companies capable of solution-based sales, such as equipment manufacturers

- System integrators (Slers) looking to enter the AI/visual inspection fields.

OEM/Bundle: Compatible with built-in equipment models

In this model, our AI inspection engine is embedded into the partner’s equipment or system and offered as an OEM product.

UI customization and rebranding are also available upon request.

Ideal for:

- Inspection equipment manufacturers and machine tool makers

- Companies looking to add new functionality to their own products.

- No upfront investment required

- We handle everything

- Performance-based rewards

- Sales tools provided

- Direct sales to customers

- End-to-end support

- Profitable pricing

- Ongoing value

- Seamless integration

- OEM-ready

- Bundled offering

- Differentiation & value

“販売力 × 技術力”を掛け合わせる

ANOMALIAの3つのパートナーモデル

紹介型:案件発掘→紹介→販売報酬

パートナー企業が、自社商材の一つとして当社ソリューションを販売・提案するモデル。PoCの実施や顧客提案の段階から当社が技術支援を行います

- 自社でソリューション営業が可能な企業

- AIや画像検査分野に参入したい装置メーカーやSIer向け

- 初期投資不要で開始可能

- 当社が提案〜受注〜サポートを担当

- 案件成約時に販売報酬(成果報酬)を還元

- 導入事例や提案資料を提供

代理販売型:自社商材として提案可能(技術支援あり)

パートナー企業が自社顧客への訪問・ヒアリングの中で当社の画像検査AIソリューションに関心がある顧客を発掘し、当社へ紹介するモデル

- 商社やシステムインテグレーター(SIer)

- 製造業顧客との関係が深いパートナー向け

- 顧客への直接販売が可能

- 提案段階〜導入・運用までを伴走支援

- 利幅確保可能な価格体系(パートナー価格)

- 定期的な製品アップデートや技術研修あり

OEM/バンドル提案型:装置内蔵モデル対応可

当社のAI検査エンジンをパートナー企業の装置やシステムに組み込み、「OEM製品」として提供するモデル。UIのカスタマイズやブランド変更も相談可

- 検査装置メーカー、工作機械メーカー

- 自社製品の新たな機能提案を検討中の企業向け

- 装置やライン制御システムに直接組み込み可能

- ロゴ・UI変更などOEM仕様に対応

- 一体型ソリューションとしての販売が可能

- 装置の差別化・高付加価値化を実現